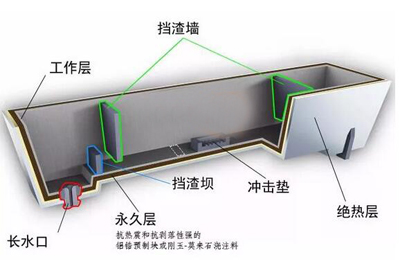

Tundish Refractory Configuration

The tundish refractory includes three parts of permanent layer castable material, working layer dry type material, water mouth and brick, slag wall series and continuous casting. So how much do you know about the five parts of the tundish? I will introduce the basic components of tundish in the following article.

Permanent Layer

The permanent layer is between the working layer and the middle cladding. permanent layer does not directly contact with steel liquid and steel slag. Usually uses aluminum and magnesium castables.

Working Layer

The working layer is in direct contact with the liquid steel and steel slag, which needs to bear the erosion and penetration of the liquid steel. The working layer mostly adopts the magnesium dry ramming, which has good slag resistance, convenient construction and easy disassembly, and can also play the role of purifying the steel liquid.

Tundish Nozzle

The tundish nozzle is the channel of the molten steel from the tundish into the crystallizer. And brick is to protect and fix the role of the mouth, not directly contact with the liquid steel. The middle wrapped mouth is mainly composed of zirconium core and high aluminum body.

Slag Wall Series

The series of refractory materials include slag wall, side plate, back plate and turbulizer, which need to bear the erosion of steel liquid, erosion and penetration of steel slag. Generally made of magnesium.

Three Pieces of Continuous Casting

The three major parts of continuous casting include big package sleeve, plug bar and submerged nozzle, which need to be flushed with the liquid steel, erosion and penetration of steel slag. The plug bar is used to control the flow of molten steel while pouring, and the big package casing and submerged nozzle are used to protect the pouring, isolate the air and prevent the secondary oxidation of molten steel. Continuous casting three large parts are mostly aluminum carbon material, and sometimes part of the zirconia is added.

Above is the tundish refractory configuration that I introduce to you, hope to be helpful to you, if you have any need about refractory materials, you can contact us for free, we have professional and personalized products and engineering services according to the actual working condition and requirements of each customer.