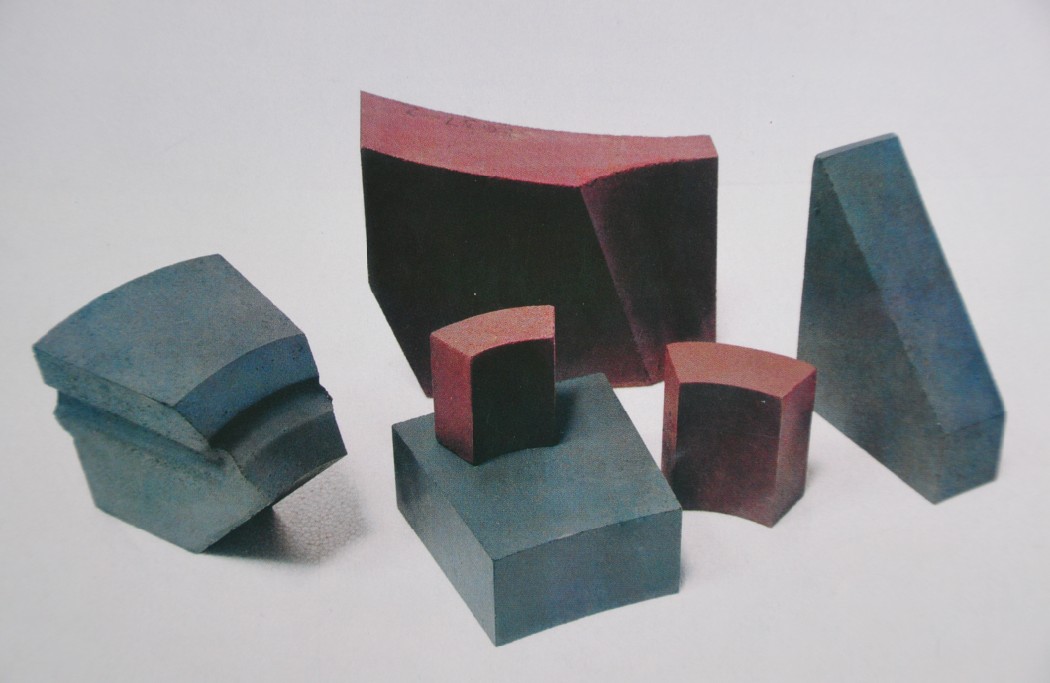

High Chrome Bricks

High chrome bricks use corundum and fused by chromic oxide and zirconium oxide as the main raw material, match with a variety of oxide powder additives, through numerical control intelligent hybrid configuration, molding, drying, in shuttle kiln high temperature burn becomes. High chrome brick have features of good thermal shock resistance, volume stability under high temperature, alkali slags resistance, and high refractoriness under load. high chrome refractory brick is mainly applied to line the sintering zone of the new dry processing of cement kilns and glass tank furnaces as checkers and the other industrial furnaces.

High Chrome Bricks Description

High chrome bricks is made of magnesia (MgO) and chromium oxide (Cr2O3) as the main ingredient, periclase and spinel as the main mineral components of refractory products. Such brick high refractoriness, high temperature strength, resistance to basic slag erosion resistance, excellent thermal stability, acidic slag also has some adaptability. The main raw material to manufacture high chrome refractory brick is sintered magnesia and chromite. Purity magnesia raw material to be as high as possible, the requirements of the chemical composition of chromite is: Cr2O3: 30 ~ 45%, CaO1.0 ~ 1.5%.

Properties of High Chrome Bricks

.High strength,

.Corrosion resistance,

.Erosion resistance,

.Excellent slag resistance,

.Good thermal shock stability.

Composition of High Chrome Bricks

High chrome bricks are mainly consist of Cr2O3, monoclinic zirconia and alumina powder. Therefore, the performance of high chromebricks is closely related to the performance of these substances. High chrome fire brick contains chromium hemitrioxide 30%, and high chrome brick is featured with acid and alkali slags resistance, and are mainly used in the isolation layer, and nonferrous smelting furnaces, etc.

High Chrome Bricks Manufacturing Process

High chrome refractory brick is made out of high quality magnesite and chrome ore fine charge mixture. According to different demands, adjust the content of Cr2O3, The product thermal stability and high temperature performance are satisfactory. High chrome bricks are widely used in the cement kiln and nonferrous metallurgical furnace etc.

Rongsheng Refractory High Chrome Bricks Specifications

| Brand | MgO % | Cr2O3 % | SiO2 % | A.P. % | BDg/cm3 | CCS.MPa | R.U.L ℃ |

| LADBMGe-8A | ≥74 | ≥8 | ≤1.5 | ≤18 | 2.98 | ≥40 | 1660 |

| LADBMGe-8B | ≥74 | ≥8 | ≤2.0 | ≤18 | 2.98 | ≥35 | 1600 |

| LADBMGe-12A | ≥66 | ≥12 | ≤1.5 | ≤18 | 3.1 | ≥40 | 1660 |

| LADBMGe-12B | ≥66 | ≥12 | ≤2.0 | ≤18 | 3.1 | ≥35 | 1600 |

| LADBMGe-16A | ≥60 | ≥16 | ≤1.5 | ≤18 | 3.15 | ≥40 | 1660 |

| LADBMGe-16B | ≥60 | ≥16 | ≤2.0 | ≤18 | 3.15 | ≥35 | 1600 |

Application of High Chrome Bricks

High chrome bricks can be used in the metallurgical industry, architectural material industry, and other non ferrous smelting furnace, etc. and also can be applied to line the sintering zone of the new dry processing of cement kilns and glass tank furnaces as checkers and the other industrial furnaces.

High Chrome Bricks Manufacturer from RS Refractory Factory

RS refractory factory is a professional high chrome refractory brick supplier that established in the early 90s of twenty century. RS refractory factory has specialized in high chrome block for more than 20 years. The advantages of RS Refractory Factory are as follows:

.Favorable location,

.Large scales,

.Good reputation,

.Favorable price,

.Professional service,

.Prompt delivery.

If you have demand of high chrome fire brick, or have some questions on high chorme brock about physical and chemical indicators, please contact us for free, we will provide you with high quality high chrome bricks.